|

|

| |

|

|

Vacuum Brazing Furnace

Vacuum Brazing Furnace | Furnace Brazing Equipment

Brazing, a joining process whereby a non-ferrous filler metal or alloy is melted and distributed between a close-fitting joint interface by capillary action, can be accomplished reliably, repeatably with low operator skill, low cost and no loss of base metal strength in a simultaneous furnace hardening/brazing cycle.

|

Details

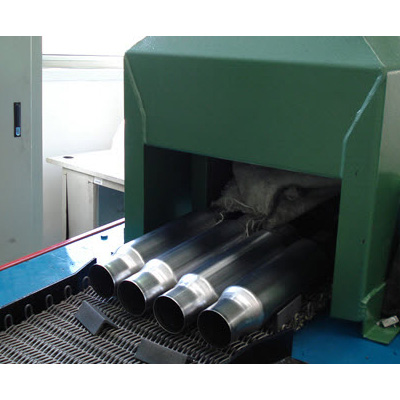

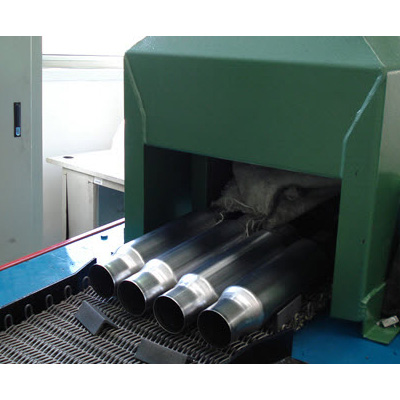

Tunnel Type Continuous Bright Brazing Furnace for Stainless Steel Brazing

Vacuum Brazing Furnace / Furnace Brazing Equipment

|

|

Brazing, a joining process whereby a non-ferrous filler metal or alloy is melted and distributed between a close-fitting joint interface by capillary action, can be accomplished reliably, repeatably with low operator skill, low cost and no loss of base metal strength in a simultaneous furnace hardening/brazing cycle. Furnace brazing can be accomplished in Continuous type furnaces are best suited to a steady flow of similar-sized parts through the furnace. These furnaces are often conveyor fed, allowing parts to be moved through the hot zone at a controlled speed. It is common to use either a controlled atmosphere or pure dry hydrogen in continuous furnaces. In particular, these furnaces offer the benefit of very low manual labor requirements and so are best suited to large scale production operations. Furnace brazing is a joining process that relies on melting, braze alloy flow and solidification of the braze alloy to form a leak tight seal and strong metallurgical bond between the mating surfaces. Special vacuum furnace brazing for nickel metal hydride materials heating treatment equipment, is able to achieve fully automated operation after feeding. | The vacuum brazing process is ideal for joining ferrous and non-ferrous metals:

ν. Stainless steel brazing

ν. Carbon steel brazing

ν. Copper brazing

ν. Nickel alloy brazing

ν. Tantalum brazing

ν. Titanium brazing

ν. Molybdenum brazing

Features:

Expert structure, smooth operation of mesh belt, stepless peed, artificial intelligence temperature controlling and the precision of temperature is 0.2%. SSR solid state relay export. It adopts decomposing gas of ammonia as protective atmosphere. The product which is brazed by this furnace is surface bright, jointing firm, non-leakage, and its targets achieve technological standard.

Application:

ν. Assemblies for food and drug production

ν. Aircraft parts and equipment

ν. Pressure vessels

ν. Tube and block assemblies

ν. Heat exchangers

ν. Structural components

ν. Exhaust ducts

ν. Medical and dental tools

ν. Excavation and drilling components

ν. Cutting tools

Filler Metals for Vacuum Brazing

ν. Nickel Alloys

ν. Silver Alloys

ν. Pure Metals

ν. Copper Alloys

ν. Gold Alloys

ν. Other Precious Metals

ν. Active Metals

Case:

Back

If this product Not the products you want: Mail , Or click here Post a buy information about product to us.

|